In the 1960’s, Dr. Strnat of the University of Dayton had shown that the entire rare earth element family presented an opportunity for developing magnetic compounds. Samarium is relatively rare in ore deposits, and Cobalt more expensive than the Iron which metallurgist wanted to use. Consequently, an alternative permanent magnet chemistry was heavily researched.

Dr. John Croat of General Motors and Dr. Masato Sagawa of Sumitomo surprised each other when they both introduced the NdFeB permanent magnet material at the MMM conference in November 1983. Dr. Croat patented the Nd2Fe14B material in the US and its melt-spinning manufacturing process. Dr. Sagawa patented the Nd2Fe14B material in Japan and its sintering manufacturing process.

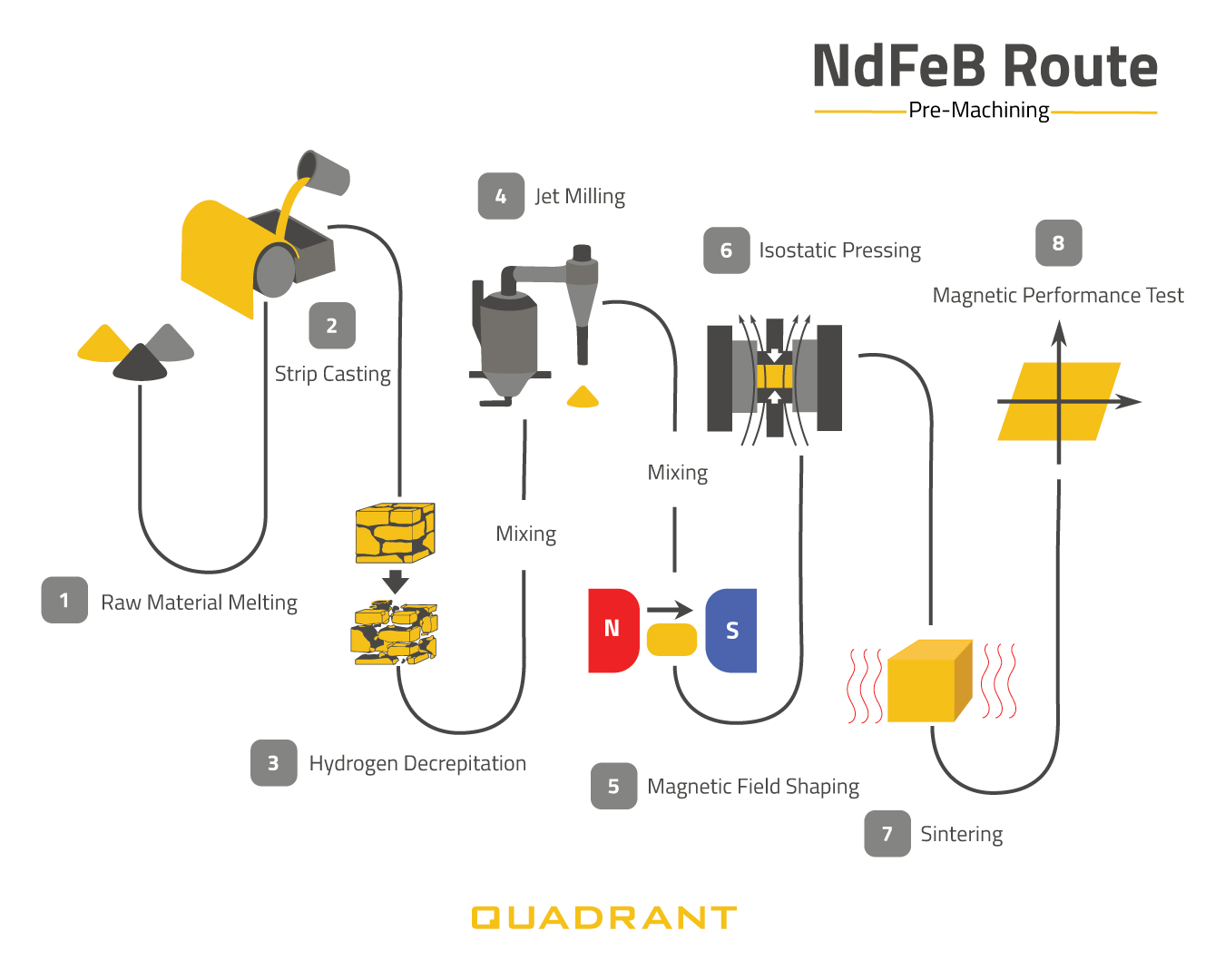

Typical high-energy NdFeB magnets are produced with a sintering process similar to that of SmCo. However, every producer uses different equipment, process steps, and raw materials to produce their large variety of available grades.

| Advantages | Disadvantages | Major Applications |

| High energy, high Induction & high coercivity at room temperature, moderate price, large range of magnetic properties. | Highly susceptible to rust & corrosion (must be coated), large temperature coefficient of Hcj, rising costs & limited resources of raw materials. | Micro motors, industrial motors, HVAC, auto (drive & accessory), aero & marine motors, drone motors, large, small, & transportation generators, speakers, microphones, consumer products, and a large variety of sensor and holding applications. Other than in some extreme conditions, NdFeB magnets can be used for most applications that require high torque & high efficiency in a small package. |

A manufacturing process begins with the prescribed metals and alloys being loaded into a vacuum furnace. The melted alloy is poured on to a cooled spinning wheel at the exact chill rate to reduce and homogenize the material’s grain size. The resulting magnet flake is subjected to Hydrogen decrepitation. This process embrittles the material at the grain boundaries so that the subsequent powder-milling process can provide a uniform material lot with the required particle size distribution.

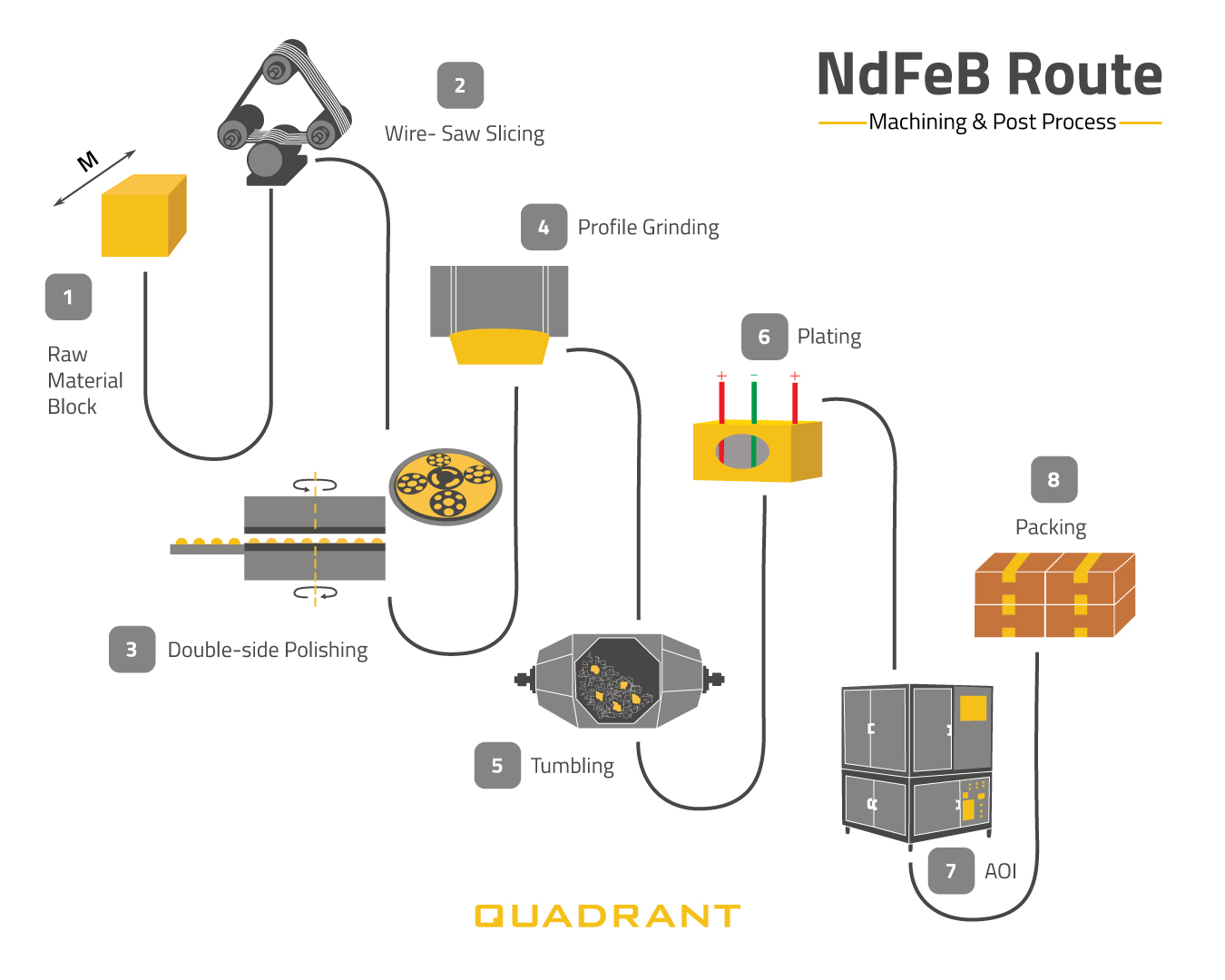

The NdFeB powder is loaded into a die where it is aligned and pressed. The resulting green compact is further densified in an isostatic press then loaded into a furnace to sinter & anneal. The finished block is fabricated to size. Those parts are treated in an acid bath to remove all oxygen & coolant from their surfaces before coating. Most processes are executed in an Oxygen-free environment and material testing stations are strategically positioned throughout.

Today’s RE2Tm14B alloys (RE = Rare Earth, Tm = Transition metal) are widely varied. Small amounts of Dy, Tb, Co, Sn, Cu, & Ga can improve Hcj and β (temperature coefficient of Hcj) without significantly sacrificing Br. Additions of Pr, Al, Nb, Zn, Mo, V, W & Ti can also affect Br, α (temperature coefficient of Induction), Hcj, & β.

Magnetic Properties of Sintered NdFeB Magnets | ||||||||||||

| Grade | Remanence | Coercivity | Max Energy Product | Temperature Coefficient | Max Working Temperature | |||||||

| Br | HcB | HcJ | (BH)max | Br | HcJ | TwMax | ||||||

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | %/°C | %/°C | ° C | ||

| N | 1.17-1.22 | 11.7-12.2 | ≥867 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | -0.12 | -0.6 | 80 | |

| 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | -0.12 | -0.6 | 80 | ||

| 1.25-1.28 | 12.5-12.8 | ≥907 | ≥11.4 | ≥955 | ≥12 | 302-326 | 38-41 | -0.12 | -0.6 | 80 | ||

| 1.28-1.32 | 12.8-13.2 | ≥915 | ≥11.5 | ≥955 | ≥12 | 318-342 | 40-43 | -0.12 | -0.6 | 80 | ||

| 1.32-1.37 | 13.2-13.7 | ≥923 | ≥11.6 | ≥955 | ≥12 | 342-366 | 43-46 | -0.12 | -0.6 | 80 | ||

| 1.37-1.42 | 13.7-14.2 | ≥875 | ≥11.0 | ≥955 | ≥12 | 366-390 | 46-49 | -0.12 | -0.6 | 80 | ||

| 1.39-1.44 | 13.9-14.4 | ≥836 | ≥10.5 | ≥955 | ≥12 | 374-406 | 47-51 | -0.12 | -0.6 | 80 | ||

| 1.42-1.47 | 14.2-14.7 | ≥836 | ≥10.5 | ≥955 | ≥12 | 390-421 | 49-53 | -0.12 | -0.6 | 80 | ||

| 1.45-1.49 | 14.5-14.9 | ≥836 | ≥10.5 | ≥876 | ≥11 | 406-438 | 51-55 | -0.12 | -0.6 | 80 | ||

| 1.48-1.52 | 14.8-15.2 | ≥836 | ≥10.5 | ≥876 | ≥11 | 414-454 | 52-57 | -0.12 | -0.6 | 80 | ||

| M | 1.13-1.17 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1114 | ≥14 | 247-271 | 31-34 | -0.11 | -0.6 | 100 | |

| 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | -0.11 | -0.6 | 100 | ||

| 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | -0.11 | -0.6 | 100 | ||

| 1.25-1.28 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | -0.11 | -0.6 | 100 | ||

| 1.28-1.32 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | -0.11 | -0.6 | 100 | ||

| 1.32-1.38 | 13.2-13.8 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | -0.11 | -0.6 | 100 | ||

| 1.36-1.42 | 13.6-14.2 | ≥1027 | ≥12.9 | ≥1114 | ≥14 | 366-390 | 46-49 | -0.11 | -0.6 | 100 | ||

| 1.39-1.44 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | -0.11 | -0.6 | 100 | ||

| 1.42-1.47 | 14.2-14.7 | ≥1059 | ≥13.3 | ≥1114 | ≥14 | 390-422 | 49-53 | -0.11 | -0.6 | 100 | ||

| 1.45-1.49 | 14.5-14.9 | ≥1059 | ≥13.3 | ≥1114 | ≥14 | 406-438 | 51-55 | -0.11 | -0.6 | 100 | ||

| H | 1.13-1.17 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-271 | 31-34 | -0.11 | -0.6 | 120 | |

| 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | -0.11 | -0.58 | 120 | ||

| 1.22-1.25 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | -0.11 | -0.58 | 120 | ||

| 1.25-1.28 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | -0.11 | -0.58 | 120 | ||

| 1.28-1.32 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | -0.11 | -0.58 | 120 | ||

| 1.32-1.37 | 13.2-13.7 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 342-366 | 43-46 | -0.11 | -0.58 | 120 | ||

| 1.36-1.42 | 13.6-14.2 | ≥995 | ≥12.5 | ≥1353 | ≥17 | 366-390 | 46-49 | -0.11 | -0.58 | 120 | ||

| 1.39-1.44 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1353 | ≥17 | 374-406 | 47-51 | -0.11 | -0.58 | 120 | ||

| 1.42-1.47 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1353 | ≥17 | 390-422 | 49-53 | -0.11 | -0.58 | 120 | ||

| 1.45-1.49 | 14.5-14.9 | ≥1059 | ≥13.3 | ≥1273 | ≥16 | 406-438 | 51-55 | -0.11 | -0.58 | 120 | ||

| SH | 1.13-1.17 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | -0.11 | -0.55 | 150 | |

| 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11.0 | ≥1592 | ≥20 | 263-287 | 33-36 | -0.11 | -0.55 | 150 | ||

| 1.22-1.25 | 12.2-12.5 | ≥907 | ≥11.4 | ≥1592 | ≥20 | 287-310 | 36-39 | -0.11 | -0.55 | 150 | ||

| 1.25-1.28 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | -0.11 | -0.55 | 150 | ||

| 1.28-1.32 | 12.8-13.2 | ≥987 | ≥12.4 | ≥1592 | ≥20 | 318-342 | 40-43 | -0.11 | -0.55 | 150 | ||

| 1.32-1.37 | 13.2-13.7 | ≥979 | ≥12.3 | ≥1592 | ≥20 | 342-366 | 43-46 | -0.11 | -0.55 | 150 | ||

| 1.36-1.42 | 13.6-14.2 | ≥995 | ≥12.5 | ≥1592 | ≥20 | 358-390 | 45-49 | -0.11 | -0.55 | 150 | ||

| 1.39-1.45 | 13.9-14.5 | ≥995 | ≥12.5 | ≥1592 | ≥20 | 374-406 | 47-51 | -0.11 | -0.55 | 150 | ||

| 1.42-1.47 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1592 | ≥20 | 390-422 | 49-53 | -0.11 | -0.55 | 150 | ||

| 1.45-1.49 | 14.5-14.9 | ≥1059 | ≥13.3 | ≥1592 | ≥20 | 406-438 | 51-55 | -0.11 | -0.55 | 150 | ||

| UH | 1.04-1.08 | 10.4-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 26-29 | -0.1 | -0.5 | 180 | |

| 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 223-247 | 28-31 | -0.1 | -0.5 | 180 | ||

| 1.13-1.17 | 11.3-11.7 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 247-271 | 31-34 | -0.1 | -0.5 | 180 | ||

| 1.17-1.22 | 11.7-12.2 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 263-287 | 33-36 | -0.1 | -0.5 | 180 | ||

| 1.22-1.25 | 12.2-12.5 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 287-310 | 36-39 | -0.1 | -0.5 | 180 | ||

| 1.25-1.28 | 12.5-12.8 | ≥915 | ≥11.5 | ≥1990 | ≥25 | 302-326 | 38-41 | -0.1 | -0.5 | 180 | ||

| 1.27-1.32 | 12.7-13.2 | ≥955 | ≥12.0 | ≥1990 | ≥25 | 318-342 | 40-43 | -0.1 | -0.5 | 180 | ||

| 1.32-1.37 | 13.2-13.7 | ≥995 | ≥12.5 | ≥1990 | ≥25 | 342-366 | 43-46 | -0.1 | -0.5 | 180 | ||

| 1.38-1.42 | 13.8-14.2 | ≥1031 | ≥12.9 | ≥1990 | ≥25 | 366-390 | 46-49 | -0.1 | -0.5 | 180 | ||

| 1.39-1.44 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1990 | ≥25 | 374-406 | 47-51 | -0.1 | -0.5 | 180 | ||

| 1.42-1.47 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1990 | ≥25 | 390-422 | 49-53 | -0.1 | -0.5 | 180 | ||

| EH | 1.04-1.08 | 10.4-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 26-29 | -0.1 | -0.46 | 200 | |

| 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | -0.1 | -0.46 | 200 | ||

| 1.13-1.17 | 11.3-11.7 | ≥820 | ≥10.3 | ≥2388 | ≥30 | 248-271 | 31-34 | -0.1 | -0.46 | 200 | ||

| 1.17-1.22 | 11.7-12.2 | ≥875 | ≥11.0 | ≥2388 | ≥30 | 263-287 | 33-36 | -0.1 | -0.46 | 200 | ||

| 1.20-1.25 | 12.0-12.5 | ≥899 | ≥11.3 | ≥2388 | ≥30 | 287-310 | 36-39 | -0.1 | -0.46 | 200 | ||

| 1.25-1.28 | 12.5-12.8 | ≥915 | ≥11.5 | ≥2388 | ≥30 | 302-326 | 38-41 | -0.1 | -0.46 | 200 | ||

| 1.28-1.32 | 12.8-13.2 | ≥970 | ≥12.2 | ≥2388 | ≥30 | 318-342 | 40-43 | -0.1 | -0.46 | 200 | ||

| 1.32-1.36 | 13.2-13.6 | ≥1003 | ≥12.6 | ≥2388 | ≥30 | 342-366 | 43-46 | -0.1 | -0.46 | 200 | ||

| 1.38-1.42 | 13.8-14.2 | ≥1031 | ≥12.9 | ≥2388 | ≥30 | 366-390 | 46-49 | -0.1 | -0.46 | 200 | ||

| 1.39-1.44 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥2388 | ≥30 | 374-406 | 47-51 | -0.1 | -0.46 | 200 | ||

| AH | 1.05-1.09 | 10.5-10.9 | ≥780 | ≥9.8 | ≥2706 | ≥34 | 207-231 | 26-29 | -0.1 | -0.42 | 220 | |

| 1.10-1.14 | 11.0-11.4 | ≥812 | ≥10.2 | ≥2706 | ≥34 | 223-247 | 28-31 | -0.1 | -0.42 | 220 | ||

| 1.14-1.17 | 11.4-11.7 | ≥812 | ≥10.2 | ≥2706 | ≥34 | 247-271 | 31-34 | -0.1 | -0.42 | 220 | ||

| 1.17-1.22 | 11.7-12.2 | ≥883 | ≥11.1 | ≥2706 | ≥34 | 263-287 | 33-36 | -0.1 | -0.42 | 220 | ||

| 1.20-1.25 | 12.0-12.5 | ≥915 | ≥11.5 | ≥2706 | ≥34 | 287-310 | 36-39 | -0.1 | -0.42 | 220 | ||

| 1.25-1.28 | 12.5-12.8 | ≥947 | ≥11.9 | ≥2706 | ≥34 | 302-326 | 38-41 | -0.1 | -0.42 | 220 | ||

| 1.28-1.32 | 12.8-13.2 | ≥970 | ≥12.2 | ≥2706 | ≥34 | 318-342 | 40-43 | -0.1 | -0.42 | 220 | ||

| www.quadrant.us | info@quadrant.us | ||||||||||||

We invite you to explore our comprehensive datasheet and discover more about the details behind our materials. Feel free to contact us here for more information.